Bump on Heat Platen presses are important tools for both crafters and small business people. You can make your own patterns on different materials, like t-shirts and tote bags. Like any machine, heat presses can have some problems.

One common problem that many users experience is the feared bump on the heat platen. These bumps can interrupt your work and cause your projects to not turn out as well as they could.

Knowing what issues can arise and how to fix them is important for keeping your heat press working well. This guide will help you handle this tricky issue easily and confidently, whether you are a beginner or have been working on it for years. Let’s explore what you need to know about bumps on heat platens.

What is a Bump on the Heat Platen?

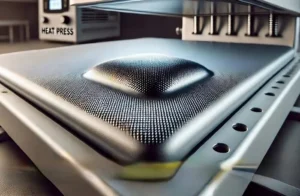

A bump on the heat platen is a high area that makes the surface of your heat press uneven. This can lead to uneven pressure when pressing, which can result in different results in your prints or transfers.

When a bump forms it disconnects the surface from the burning source. Some places may be cooler than others. This inconsistency can cause issues like fading, incomplete transfers or burns.

Small bumps can have a big effect on your projects. They can happen due to the accumulation of waste or damage to the Earth’s surface over time. Understanding what a bump is helps keep your heat press tools in good working order.

Causes of Bumps on Heat Platens

There are a variety of potential causes for bumps on heat plates. A typical cause is the accumulation of filth and dust. Uneven heating can generate pimples, and equal tiny bits can do it.

Inconsistent temperature levels are another factor. Over time, bumps can emerge if the plate’s temperature distribution is uneven. Another major contributor to this issue is worn or damaged pads.

Wear and tear causes these pads to lose their flat surface which creates pressing issues. Methods that are not used correctly further add to the problem. If you press down on your press too hard, you might alter the surface of the world.

Your equipment can also be affected by ambient conditions including humidity. Surfaces can be bent and bumps might become worse over time if they are exposed to moisture.

Prevention Techniques for Bumps on Heat Platens

Watch your heat platen closely and check it regularly for any bumps. Look for signs of injury or damage. By fixing small problems first you can save time and money and prevent bigger issues.

Another helpful tip is to make sure the temperature is set right. To prevent warping or damage from heat, always follow the manufacturer’s directions. When storing the platen, make sure to use a cover to keep it from becoming uneven with time.

Verify the heat press’s compatibility with any material before using it. When two substrates are incompatible, the resulting pressure distribution is often uneven.

Keep your heat platen clean at all times. A simple wipe down after each usage will maintain the surface flat and clear of any sticky residues.

Troubleshooting and Fixing a Bump on the Heat Platen

If you find a bump on your hot plate, stay calm. First, check how big the problem is. Please turn off and unplug your press for safety. Check the surface of the platen closely. Small pieces of dirt can sometimes make it look like there’s a bump.

Use a soft cloth to wipe it clean and remove any leftover dust that might be causing the issue. If you see anything unusual, look for bending or damage. A bent platen might need a professional to fix or replace it.

You can check if the temperature is even across different spots on the plane with an infrared thermometer. If the heat is uneven, it may point to bigger problems that need fixing.

For small bumps, gently pressing while heating can help smooth them out over time. Wait for things to cool down before touching any objects to prevent burns or injuries.

Maintenance Tips for a Smooth-Running Heat Press

Taking care of your heat press regularly is important to keep it working well. Clean the heat platen after every use. Build-up from materials can impact how well something works.

Check the pressure settings often. Keeping the right pressure helps you get better results and makes both the platen and your moves last longer. Check all wires and connections regularly.

Check for any wear or damage that might cause electricity problems in the future. Lubricate the moving parts following the instructions from your maker. This easy step helps everything work well without putting extra stress on the parts.

Keep your heat press in a dry place with consistent temperatures to avoid rust or damage. Paying attention to these details will help you avoid common issues and guarantee good quality whenever you start a new job.

Conclusion

Keeping your heat press in good shape is important for it to work well. By knowing about common problems, such as a bump on the heat plate, you can take steps to stop issues from happening in the first place.

Regular checks and good upkeep will keep your equipment working well. Inspect it thoroughly for indications of damage or wear. Watch for any signs of wear or damage.. If you run into a problem.

learning how to solve it quickly will save you time and stress later on. Putting in some extra work to take care of your machine will make it last longer and improve the quality of what you produce.

With these tips you’ll be ready to handle any problems that come up with your heat press. Follow these tips for easier operations and enjoy making beautiful designs without any problems with your heat platen.